The unprecedented shortage of infant formula in the U.S. may come as a surprise to many. But as far back as 2020, some industry observers predicted such an event would happen. They foresee the pandemic to cause significant global supply chain disruptions, which will continue in 2022.

True enough. Today, logistics operations and supply chain management are as complex and costly. But aside from COVID, numerous other factors have aggravated—and are expected to challenge further—the volatile global supply chain.

Take a deep dive into these pressing issues and explore solutions to mitigate the impacts on your business.

The Importance of a Healthy Supply Chain

Think of the supply chain as a series of water pipes supplying water to a neighborhood. Water will not flow efficiently if one part of the series is clogged. The increased pressure may lead to the potential breakdown of other pipes, causing the water supply to be sparingly available or completely unavailable.

If this scenario happens, people in the neighborhood will be dissatisfied.

A bottleneck in your supply chain has similar effects. Any interruption in the flow of raw materials, supplies, or end products (whether from your supplier to your warehouse or your warehouse to your customers) leads to higher operations costs.

It also affects the availability of commodities, the timeline of order deliveries, and the prices of goods—factors that impact customer experience, satisfaction, and, ultimately, brand loyalty.

Read more: Nearshoring vs. Reshoring: Which Is the Practical Response to Supply Chain Disruptions?

Global Issues Driving Supply Chain Disruptions in 2023

On the Supply Side:

1. China’s COVID Crisis

While the rest of the world has started easing restrictions and showing a semblance of normalcy, China continues implementing lockdowns and other stringent COVID responses. These measures gravely impact China’s economy and the rest of the world.

With China accounting for around 12% of global trade, the disruptions in the country’s manufacturing, transport, and other vital industries ripple through the world’s supply chain.

Many U.S. businesses, including over 200 Fortune Global companies, procure raw materials, labor, and goods from China. But as strict mobility restrictions force many factories in the Asian country to suspend or downsize operations, exporting materials and goods from the country has become highly challenging.

Pre-pandemic, shipping products from a warehouse in China to the U.S. takes about 40 days. Today, the turnaround takes 74 days longer. Some U.S. manufacturers have resorted to taking costly and inefficient measures to meet production and delivery timelines, such as purchasing additional trucks and increasing employee headcounts.

2. Russia-Ukraine War

The impact of the friction between Russia and Ukraine is not contained between the two European countries. The rest feel the brunt as the war immobilizes Ukraine’s and partly Russia’s export sectors.

Consider these:

- Russia and Ukraine export about 80% of the world’s sunflower oil, 30% of the world’s wheat, and 19% of the world’s corn.

- Before the conflict, Ukraine shipped more than 70% of its exports, 99% of which were corn.

- Between 4.5 and 5.5 million tons, or 30% to 40% of the world’s total exports, pass through the Black Sea.

Since the war broke out, major global container lines, such as MSC and Maersk, have suspended sailing operations in the Black Sea — amplifying the supply chain management woes brought by hundreds of trapped merchant vessels in the region.

Additionally, many European countries have banned Russian vessels from their ports. This sanction forced Russian ships to reroute, resulting in bottlenecks in other sizeable European container ports and ripples through other ports outside the continent. Some crucial ports in different parts of the world experience the worst recorded congestion.

All these factors further exacerbate the already-tight global supply chain, resulting in a domino effect that materializes in:

- A spike in the prices of sunflower oil, wheat, corn, and other commodities

- A seven-fold increase in the cost of transoceanic container shipping

- An additional 1% to 5% marine insurance costs for vessels passing through the Black Sea

- A shortage of food supply in Africa and Middle East countries that rely on exports from the involved region

On the Demand Side:

1. Evolving Consumer Demands

The COVID-19 pandemic drove the exponential growth of the global e-commerce industry. Amid the health crisis, economic stimulus packages have prompted increased consumption and demand for durable goods mainly brought online.

E-Commerce also altered consumer buying habits for good. Finding satisfaction in the experience, many consumers embrace online shopping, favoring brands that meet their demands for good speed, customer service, and overall experience.

However, supply chain challenges make it difficult for businesses to respond. The unprecedented uptick in customer orders put additional pressure on carriers dealing with insufficient shipping containers, congested ports, and other freight transportation issues.

2. Driver Shortage

Logistics management woes don’t end once a product reaches American soil. U.S. merchants must overcome another bottleneck — ground transport to get products into store shelves.

According to the American Trucking Association, the U.S. saw a record-high shortage of 80,000 drivers in 2021. If this trend continues, America could face a deficit of up to 160,000 drivers by 2030.

Why are truck drivers leaving the road? Industry analysts believe that there is no single reason driving the shortage. Instead, it is a result of a combination of various factors, which include:

- Soaring fuel prices

- Pandemic-related safety concerns

- Decrease of operational driver training schools since the pandemic

- High driver retirement and low retention rates

Read More: 5 Most Outsourced Back Office Support Services and Keys to Solutions That Work

The Effects on the U.S. Supply Chain

1. Record-Breaking Inflation

Amid skyrocketing demand and scant supply, prices of goods and services in the U.S. soar rapidly. In 2021, the country saw an 8.5% inflation rate hike — its highest in more than 40 years. And although the annual inflation has improved since April 2022, the Consumer Price Index continues to climb with an 8.3% increase.

2. Basic Commodity Shortage

Consumption resumes as consumers learn to live with the virus. But instead of commodities, many customers see “out of stock” notices on store shelves—hinting at the gravity of the supply chain strain.

Even online shoppers have a hard time purchasing everyday items. According to Datasembly, about 31% of grocery products browsed by online consumers in the first week of April 2022 were unavailable.

3. Wage Hike

Since about 72% of America’s freight relies on truck transportation, the driver shortage has significantly contributed to commodities scarcity and rising costs. It has also compelled many companies to increase driver wages and offer sign-on bonuses.

Among them are Walmart and KLLM. The retail giant now pays salaried drivers $110,000 in their first year—double the average salary of long haul drivers. Meanwhile, trucking company KLLM has implemented the highest salary increase in its 60-year history.

What You Can Do To Mitigate the Impacts of Global Supply Chain Disruptions

Logistics Outsourcing

Some industry analysts foresee the global supply chain shortages to last up to two years. Efficient logistics and supply chain management is crucial to maintaining healthy cash flow and weathering the crisis.

With shipping costing more and taking longer than usual, businesses cannot afford to cause bottlenecks in their supply chains further. Every minute of delay makes the entire operation even more expensive, and any additional expense could lead to devastating impacts.

This is why many U.S. businesses delegate logistics and supply chain management to a reliable back-office outsourcing provider. The practice enables companies to:

- Maximize in-house productivity to speed up turnaround time.

- Save significantly on back-office labor and overhead costs.

- Focus time and financial resources on other critical logistic functions.

- Increase agility and resilience with scalable logistics management services.

Companies specializing in logistic back-office outsourcing provide the most cost-effective options to:

- Manage inventory levels.

- Track product shipments, handling, and returns.

- Prepare and manage documentation.

- Conduct data entry and management.

Customer Service Outsourcing

During last year’s holiday period, the U.S. market saw a peak in spending since the pandemic. However, it was also when the country recorded the most prolonged sustained period of customer satisfaction deterioration in two and a half decades—highlighting the massive imbalance between supply and demand.

Although the global supply chain is volatile, customers expect and deserve nothing less than excellent customer service. Research shows that customer service significantly influences purchase decisions and brand loyalty. According to Zendesk’s 2022 CX Trends report:

- 81% of consumers say a positive customer service experience encourages repeat purchases.

- 70% of shoppers have decided to buy from a brand based on the quality of its customer service.

- 78% of consumers said they would switch to a competitor following multiple poor customer service experiences.

But how can brands deliver quality customer service if the supply chain is susceptible to factors beyond one’s control? The answer: focus on what you can control. Yes, the causes of delivery delays may be beyond your control, but how you respond to customers’ queries, complaints, and even frustrations are.

Customers expect consistent delivery updates and fast, personalized customer service. They also want authentic, empathetic service that offers the best solution and after sale care possible — 24/7. The most pragmatic way to achieve all these is through customer service outsourcing.

Building and managing an in-house customer support team is impractical, considering the financial strains of supply chain disruptions to businesses. Aside from hiring and training the best people for the job, you must invest in procuring and maintaining sophisticated infrastructure and technologies.

A reputable customer service outsourcing partner offshore or nearshore can equip you with everything you need to deliver an excellent customer experience—from job-ready agents to sophisticated technical infrastructure—in a short period and at lower rates.

Accounting and Bookkeeping

The supply chain crisis has compelled business owners to change where and how they source their commodities. In other words, they would cooperate with new manufacturers, creating new business relationships and computing unaccustomed taxing regimes. With so many uncertainties going on about logistics and costs, it becomes tough to manage and foresee financial risks.

But outsourcing accounting and bookkeeping services can help you evaluate the roots of the problems and build resilience for your business. To secure the safe delivery of goods, they can guide you in implementing payment systems with the manufacturers, rewarding them for their willingness to adapt up-to-date processes and procedures.

Here are other ways in which accounting and bookkeeping services can help minimize risks of supply chain disruptions:

- Assess supply chain situations: Study where lies the financial excesses and shortages and obtain actionable insights.

- Open-book accounting: Ensuring visibility and transparency of the cash ins and outs across supply chains.

- Back-up inventory: Reduce revenue loss in sales.

- Comparing prices: Evaluate make-or-buy decisions across several warehouses.

Read More: A Glimpse Into the 5 Latest and Most Powerful Customer Loyalty Trends of 2022

Read On To Know More About the Issue

The 5 Biggest Supply Chain Issues

Supply chains are the bloodline of the global business ecosystem. The process streamlines obtaining products from the manufacturers to retailers—and finally, to consumers. However, supply chains are vulnerable. The system could eventually fall into shambles when there’s a sudden shift in consumer demand or unforeseen global events.

Understanding supply chain issues is the pathway to resolving them. So, here are five main factors contributing to supply chain disruptions:

- The surge of e-commerce: E-commerce was already reaching incredible heights pre-pandemic. But COVID-19 further fueled its success, proving that online product demands are still soaring. Consumers won’t need to buy products physically, possibly straining supply chain activities.

- World conflicts: Ukraine, one of the major food and energy suppliers, plays a massive role in the global supply chains. Hence, the recent Russian invasion led to a severe food crisis and a higher cost of living.

- Outdated technology: Companies tend to stumble when the tools used for their supply chains need modern technological features. This includes the ability to manage complex data and make smart decisions. Business owners should adopt new systems to ensure supply chain resilience.

- Declining resources: A labor shortage can contribute to the downturn of supply chains. For instance, more production line workers are needed to manufacture commodities. Companies also rely on truck drivers for product transportation. But currently, most workers are retiring—and the younger generations don’t seem eager to take on these skilled jobs. This could lead to a high employee attrition rate, causing stagnant supply chain processes.

- Disorderly logistics: When we’re dealing with supply chains, we also manage whatever goes on behind the scenes—such as the order management system, warehouse management systems, as well as retailers. Meshing the patchwork of systems together could be expensive and time-consuming. But cloud-based supply chain solutions could help entrepreneurs keep track of their businesses and mitigate supply chain problems.

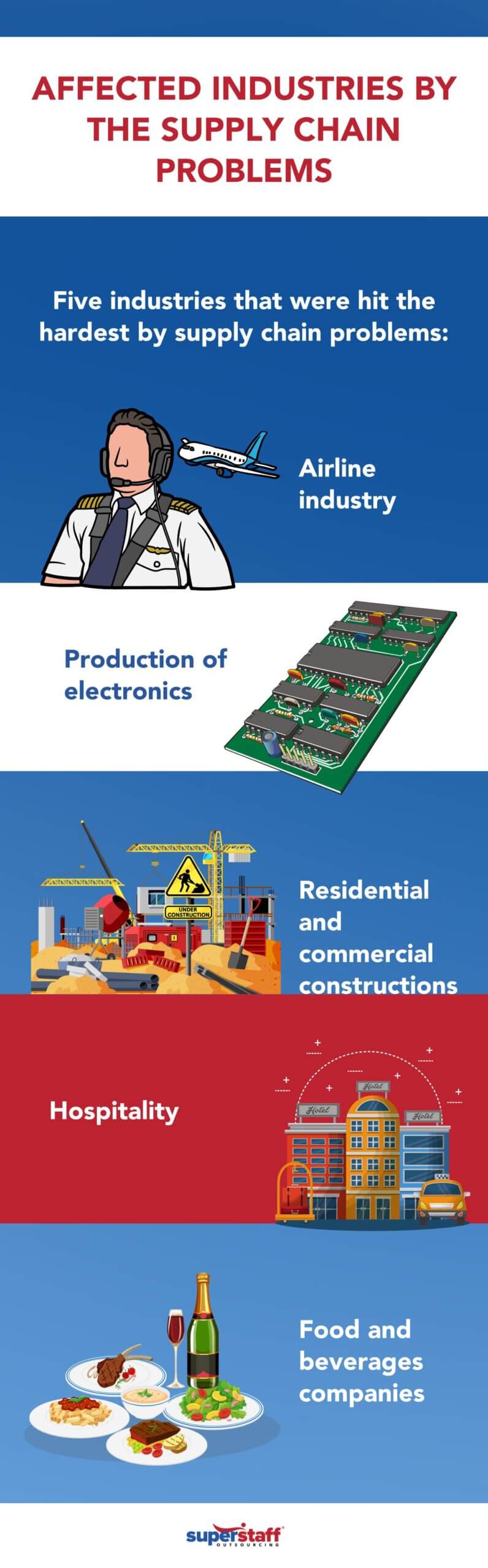

Affected Industries by the Supply Chain Problems

Product shortages and empty shelves are the results we anticipate when we think of a supply chain crisis. Companies can hardly do business when there are no products in the market. Because of that, affected businesses should take pre-emptive measures to reduce the risks arising from disrupted supply chains.

The Impacts of Climate Change on Global Supply Chains

It’s hard not to notice the drastic environmental changes due to the climate crisis. The rise of sea levels, global warming, severe storms—they’re all over the news. Yes, the pandemic was already the antagonist to the supply chain system. But extreme weather exacerbates the issue. While COVID-19 poses a “temporary problem,” climate change presents a “long-term threat” to logistics. Because of this, supply chain disruptions may occur.

Here are some climate change impacts on supply chains:

- Transition risks: Regulations mandate lower carbon technologies in economic transactions. This could push assets for non-renewable energy, like fuel and gas, to a standstill.

- Physical risks: Floods and wildfires are event-driven, whereas storms and droughts are chronic climate trends. Supply chain leaders may need help to ship raw materials for business operations and outbound product delivery.

- Climate change opportunities: The need to be environmentally conscious calls for a change in consumer buying behavior. With that, they’d be more inclined to purchase products or commodities that may reduce their carbon footprint.

Read More: Your Guide to Back-Office Solutions: Importance, Types, and Advantages

Outsourcing Logistics in Supply Chain Management

A modern problem requires a modern solution. With effective supply chain planning, retailers may observe a profitable shift in their business. And one solution for this is logistics outsourcing.

Let’s take a look at some considerations when outsourcing logistics:

- Size and intricacy of business: When managing a complex or large-scale firm, it would be ideal for getting logistic services from a BPO provider. Consequently, you can organize your supply chains effectively and maximize your resources.

- Lack of expertise: Not all of us are born to be jack-of-all-trades. And sometimes, it’s better to leave certain things to the professionals. So, if you need to become an expert in the logistics sector, it’s best to outsource them from a credible provider.

- Economies of scale: Businesses seek to reduce overhead costs as much as possible. When you outsource your logistics, you can enjoy the full benefits of the economies of scale offered by your service provider. As a result, you don’t need to waste your time and money on shipping and costs, warehousing, and inventory planning.

- Seeking flexibility: We live in a fast-paced world. So, we must be on top of our game—especially when the business ecosystem is getting competitive. This is why your outsourced logistics specialist is your holy grail. They can help your firm adapt quickly to the ever-changing consumer demands and market conditions while upkeeping control of your supply chains.

Drive Down Logistics and Supply Chain Management Costs With a BPO Partner

Search for a BPO that offers comprehensive solutions to help your business respond to supply chain disruptions. With scalable customer service and logistics back-office outsourcing solutions, you can improve quality and speed and meet customer expectations — while driving down costs.