Order delays. Customer complaints. Inventory errors. When fulfillment breaks down, your entire business takes a hit. What starts as a few late shipments or mispicked items can quickly snowball into poor reviews, rising return rates, and lost customer trust. For fast-growing retailers and e-commerce brands, this is often the moment when operations begin to outpace internal capacity.

As order volumes climb and customers expect faster, more accurate delivery, many in-house teams struggle to keep up. The more complex your product catalog, shipping zones, or promotional cycles, the harder it becomes to manage everything without delays or costly mistakes. That’s why more companies are choosing to outsource order processing—not just to catch up, but to stay competitive.

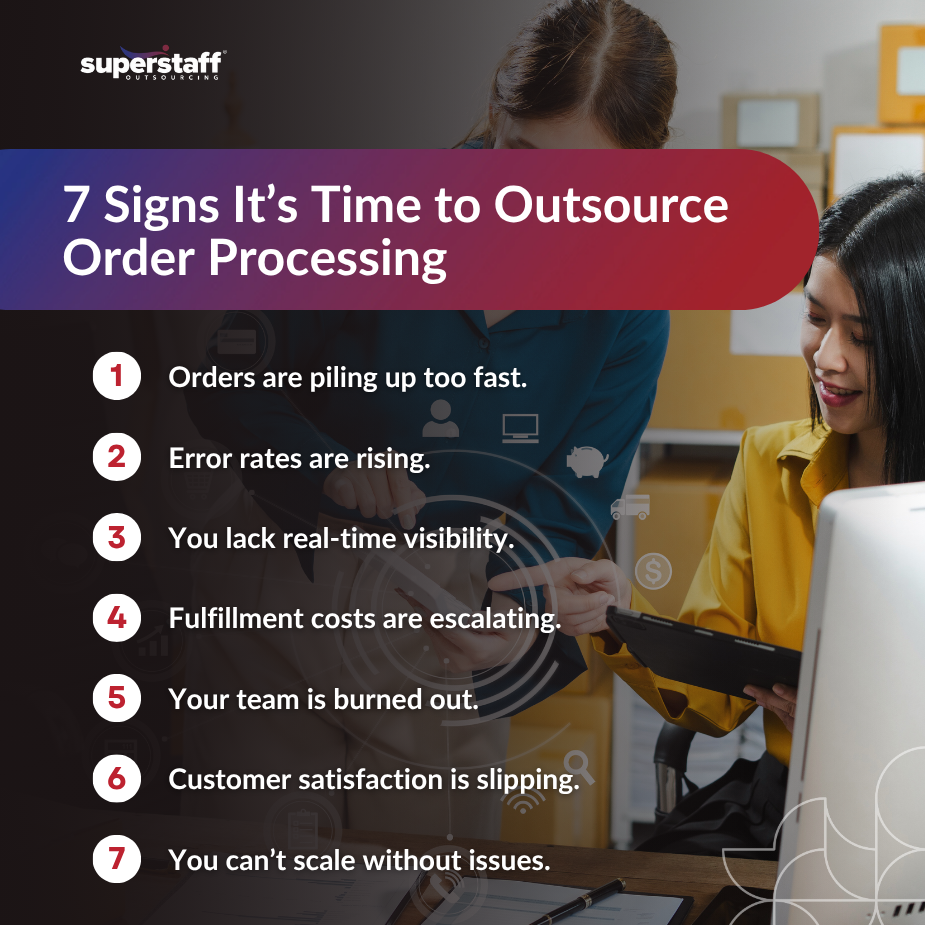

How To Know It’s Time to Outsource Order Fulfillment and Processing: 7 Signs To Watch Out For

This blog will walk you through the seven biggest signs that your current fulfillment setup is becoming a bottleneck. From growing error rates to burnt-out staff, we’ll show how these operational warning signs can silently stall your growth.

And more importantly, we’ll explore how strategic outsourcing can provide the scalability, efficiency, and customer satisfaction you need to move forward with confidence.

#1: Orders Are Piling Up Faster Than You Can Fulfill

The global e-commerce fulfillment market reached $123.7 billion in 2024, marking a 12.9% YoY increase—and is on course to hit $272 billion by 2030. These numbers show how critical order processing has become for online businesses. As orders grow, the demand for speedy fulfillment increases alongside them.

Rapid sales growth is a good problem—until your fulfillment team can’t keep up. While increased demand signals business success, it also exposes capacity limits. If your fulfillment process can’t scale with sales, you risk missing delivery windows and frustrating customers.

Delayed shipments often result in:

- Frequent backorders or stockouts

- Overtime becoming standard

- Slower pick, pack, and ship cycles

These delays don’t just hurt customer satisfaction—they can cause permanent damage to your brand. You lose future revenue every time a shopper chooses a competitor due to poor fulfillment performance. To avoid these issues, many companies choose to outsource order processing to partners that can ramp up or down based on demand.

Beyond speed, fulfillment issues also reveal gaps in accuracy.

#2: Your Error Rate Is Hurting Your Brand Reputation

Incorrect or duplicate shipments lead to costly returns and lost trust. In the age of instant feedback, a single mistake can trigger a cascade of bad reviews and social media backlash.

Watch for these red flags:

- Surge in return volume due to mispicked items

- Customer complaints about damaged or missing products

- Negative reviews tied to fulfillment, not product quality

When your internal team is rushing to meet demand, accuracy suffers. The cost of fixing those errors—restocking, reshipping, or refunding—can quickly cut into your margins. Companies that outsource order processing benefit from trained agents, barcode scanning systems, and fulfillment SLAs that ensure accuracy and consistency.

Errors often stem from strained internal systems that lack visibility.

#3: You Lack Real-Time Order and Inventory Visibility

You can’t manage what you can’t see—especially when customer expectations are rising. If you’re relying on manual spreadsheets or disconnected systems, your visibility is limited and outdated.

This lack of transparency leads to:

- Manual tracking prone to human error

- No centralized dashboard for monitoring order statuses

- Limited insight into fulfillment KPIs like cycle time or fill rate

Customers now expect real-time tracking updates and accurate inventory counts before they click “Buy Now.” By choosing to outsource order processing to a tech-enabled partner, you gain access to platforms that integrate with your systems, giving you (and your customers) full visibility into every step of the order lifecycle.

Alongside visibility gaps, operational costs start creeping up.

#4: Your Fulfillment Costs Are Growing Out of Control

In-house fulfillment often hides true costs until it becomes unsustainable. Labor, warehousing, shipping, and tech expenses add up fast—especially during growth spikes or peak seasons.

Watch for these cost drivers:

- Frequent overtime and seasonal hiring

- High warehousing fees with low efficiency

- Inconsistent carrier pricing and late fees

Outsourcing partners operate at scale and pass those cost efficiencies on to you. When you outsource order processing, you convert fixed costs into variable ones, eliminate unnecessary overhead, and gain predictable, transparent pricing.

While costs rise, your team may be feeling stretched thin.

#5: Your Team Is Burned Out and Turnover Is High

Burnout in fulfillment teams leads to lower accuracy, slower delivery, and higher HR costs. During peak periods, even the best teams hit a breaking point.

Warning signs include:

- Absenteeism and attrition in fulfillment roles

- Rising HR overhead for recruitment and training

- Employee dissatisfaction during peak seasons

Hiring and retaining warehouse staff is increasingly difficult in competitive labor markets. By choosing to outsource order processing, you free your internal team from repetitive, manual tasks and create space for them to focus on higher-value work.

And when burnout affects CX teams too, customer loyalty suffers.

#6: Customer Satisfaction Scores Are Slipping

Fulfillment delays and errors have a direct impact on customer loyalty and NPS. Today’s buyers expect near-instant shipping updates and smooth delivery experiences—especially in competitive industries like fashion, electronics, or home goods.

Common signals of slipping customer satisfaction:

- Increase in WISMO (Where Is My Order?) calls

- Lower CSAT and NPS scores

- Poor unboxing experiences from rushed or substandard packing

Partnering with an outsourced fulfillment provider helps mitigate these issues. When you outsource order processing, you tap into teams trained to prioritize speed, accuracy, and presentation—ensuring that your customers receive the quality service they expect.

If these issues sound familiar, you may be spread too thin to scale.

#7: You Can’t Scale Without Compromising Quality

Growth should be exciting—not a cause for logistical panic. But if your current fulfillment setup struggles to handle spikes, launches, or multi-channel orders, scaling could compromise your product quality or delivery promises.

Here’s how this challenge shows up:

- Inability to expand to new markets or SKUs

- Bottlenecks during seasonal surges

- Reactive rather than strategic fulfillment planning

Choosing to outsource order processing gives your business room to grow. Scalable BPO partners offer global reach, specialized tools, and the flexibility to handle volume fluctuations—all without sacrificing quality or customer satisfaction.

These signs all point to the same solution—strategic outsourcing.

Know the Signs—And Act Before You Hit a Breaking Point. Outsource Order Processing Today.

Fulfillment bottlenecks are more than growing pains—they’re signs your operations need support. When your internal systems and teams can no longer keep pace, your reputation, revenue, and customer loyalty are all at risk.

From high error rates and poor visibility to rising costs and burned-out teams, these red flags demand attention. The good news? You don’t have to go it alone.

By choosing to outsource to the Philippines, you unlock the power of specialized expertise, flexible scale, and consistent performance.

SuperStaff’s order processing solutions are designed to help growing companies streamline fulfillment, reduce overhead, and improve customer satisfaction—without missing a beat. Let’s talk about how outsourcing fulfillment can unlock your next phase of growth.